Giuseppe Oriani

Skype: caba-agritech

CaBa Industrie srl

Overview:

Germany, France, Austria, Switzerland, Spain, Portugal, Hungary, Poland, Slovakia, Czech Republic, Slovenia, Croatia, Greece, South Africa, China, Australia, Georgia

We're looking for dealers and distributors in North America and Mexico

Who we are - Company presentation

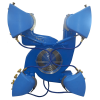

541 Vicar air unit More info

Category:

Description:

The Vicar 451 air unit is a cannon sprayer for tall trees, greenhouses and open field crops. Its particular design and the bigger size of the turbine allow the group to have an exceptional rate produced air / absorbed power that will surprise you by significantly reducing the consumption of your tractor. This air unit could be used for blowing away the snow from trees too, avoiding them to fall down.

PDF:

Features:

Machinery and Equipment End Product:

540 Vicar air unit More info

Category:

Description:

The Vicar 540 is our flagship machine. It is particularly effective in orchards and higher cultivation systems and allows, thanks to its bigger turbine, to move a major air volume than other models, without renouncing to the precision that characterizes Vicar sprayers. Trailed sprayer with a 200 to1500 L tank and 540 air unit, equipped with 500mm diameter turbine, 1 mouths and 8 nozzels.

PDF:

Features:

Machinery and Equipment End Product:

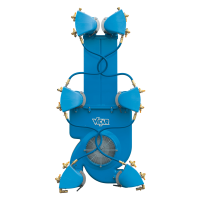

456 Vicar air unit More info

Category:

Description:

The Vicar 456 group is specific for trellis systems with an inter-row distance bigger than 2.50 meters. The powerful Ø 400 Duplex turbine will fulfil your expectations even in difficult conditions such as vigorous implants (eg GDC) and windy days, obtaining effective, on target and uniform treatments. Trailed sprayer with a 200 to 1500 L tank and 456 air unit, equipped with 400mm diameter turbine, 6 mouths and 12 nozzels.

PDF:

Features:

Machinery and Equipment End Product:

451 Vicar air unit More info

Category:

Description:

The Vicar 451 air unit is a cannon sprayer for tall trees, greenhouses and open field crops. The particular design of the turbine allows the group to have an exceptional rate produced air / absorbed power that will surprise you by significantly reducing the consumption of your tractor.

Trailed sprayer with a 200 to1500 L tank and 451 air unit, equipped with 400mm diameter turbine, 1 mouths and 8 nozzels.

PDF:

Features:

Machinery and Equipment End Product:

460 Vicar air unit More info

Category:

Description:

The Vicar 460 group is the flagship of the Vicar vineyard line. The results that can be obtained with this group are comparable, in terms of efficiency and drift, to recovery machines, despite their low power consumption and their compact dimensions.

After efficiency tests issued by BBA, it has been proved that more than 90% of the spray reaches the target.

Trailed sprayer with a 200 to 1500 L tank and 460 air unit, equipped with 350mm diameter turbine, 6 mouths and 12 nozzels

PDF:

Features:

Machinery and Equipment End Product:

440 Vicar air unit More info

Category:

Description:

The Vicar 440 group is a valid and up-to-date product for narrow vineyards with large slopes, thanks to its low power consumption and small size.

Trailed sprayer with a 200 to 1500 L tank and 440 air unit, equipped with 350mm diameter turbine, 4 mouths and 12 nozzels

PDF:

Features:

Machinery and Equipment End Product:

430 Vicar air unit More info

Category:

Description:

The Vicar 430 air unit is recommended for “pavillion” and trellis systems and represents a perfect balance between air produced and power supplied. To this air unit can be attached two specific spraying heads for tall trees or a cannon spraying head for operations in greenhouses or in open fields. Trailed sprayer with a 200 to1500 L tank and 430 air unit, equipped with 350mm diameter turbine, 2 mouths and 10 nozzels

PDF:

Features:

Machinery and Equipment End Product:

PA 20 More info

Category:

Description:

The tool-carrier PA 20is a double and economic machine for row cleaning and leaf canopy management. It is mountable both on a front lifter and on the ballast of the tractor. After work it is then possible to replace the trimmer on a proper standing foot, reducing the user’s risks..

The tool-carrier is equipped with a 400mm hydraulic horizontal ram on both sides and has the possibility to incline its arms until 90°, making easier going in and out of the row.

The machine is equipped with an electro-hydraulic distributor to control all its movements. In case of motorized tools, it is necessary to provide an oil flow of 20-25L/min, according to the munted tools.

The PA 20 could work in rows between 1,80m and 4,50m width, depending on the tools mounted on it.

PDF:

Features:

Machinery and Equipment End Product:

PA 10 More info

Category:

Description:

The tool-carrier PA 10 is a simple and economic machine for row cleaning and leaf canopy management. It is mountable both on a front/rear lifter and on the ballast of the tractor. After work it is then possible to replace it on a proper standing foot, reducing the user’s risks.

The tool-carrier is equipped with a 400mm horizontal ram (mechanical or hydraulic) and, in A model, with a vertical ram of the same length.

The machine takes its oil supply from the hydraulic distributor on the tractor while, in case of a motorized tool, the oil amount changes according to the tool itself.

PA 10 is available in following models:

- PA 10 SM: 3 points mounting and mechanical horizontal ram

- PA 10 SH: 3 points mounting and hydraulic horizontal ram

- PA 10 A SM: connection with frontal bracket and mechanical horizontal ram

- PA 10 A SH: connection with frontal bracket and mechanical horizontal ram

PDF:

Features:

Machinery and Equipment End Product:

CT80 More info

Category:

Description:

CT 80 trimmer is a single machine with a robust column structure, projected for carrying out mechanical fruit thinning in orchards, improving the quality of fruits and favouring the tree’s balance. It is moreover usable with different tools of Lotti range for leaf canopy management. It must be mounted on the front part of the tractor on a 2nd category lifter. After work it is then possible to replace the trimmer on a proper standing foot, reducing the user’s risks.

The trimmer’s column is equipped with a vertical ram of 1000mm that allows to work on the entire extension of the leaf canopy. In addition, the column is tiltable both positively and negatively, making easier going in and out of the rows, as the trimmer could be easily placed in its central position. The different cylinders that control the rams enable also to tilt the fruit thinner, making its action effective in any orchard system it is applied.

The machine needs an hydraulic supply between 20-25L/min. oil flow.

CT 80 is controlled by an electro-hydraulic joystick to be kept in the tractor’s cabine, which enables you to carry out all its movements.

- CT 80 N: that uses the tractor’s distributor for its movements

- CT 80 E: with electro-hydraulic distributor

PDF:

Features:

Machinery and Equipment End Product:

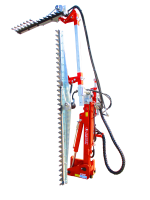

CT50 More info

Category:

Description:

The CT 50 trimmer is a double machine with double-upright frame, usable with different Lotti tools for leaf canopy management. It is mounted on the front of the tractor with a quick coupling bracket equipped with a clamp. After work it is then possible to replace the trimmer on a proper standing foot, reducing the user’s risks. The small dimensions of the central part, allows to always have a good visual during any operation.

The trimmer has a vertical ram of 400mm on both sides, combined with the possibility to adjust both posts positively and negatively. Thanks to two horizontal rams of 400mm each, it is even possible to work in rows whose width is between 1,80m and 3,00m.

The machine needs a hydraulic supply with a minimal oil flow of 20L/min.

All the movements are regulated by an electro-hydraulic control box to be kept in the tractor’s cabine.

PDF:

Features:

Machinery and Equipment End Product:

CT20 More info

Category:

Description:

The CT 20 trimmer is a single column machine projected for vineyard and usable with different Lotti tools for leaf canopy management. It is mounted on the front of the tractor with a quick coupling bracket. After work it is then possible to replace the trimmer on a proper standing foot, reducing the user’s risks.

The trimmer’s column is equipped with a vertical ram of 700mm and is adjustable both positively and negatively, making easier going in and ouot of the rows, as teh machine could be placed in its central position. Even the post could be adjusted positively and negatively, enabling tthe work in difficult conditions too.

In addition, it is possible to mount on this machine a bridge-shaped frame, making possible to work on both sides and on the top of a single vineyard row.

The machine needs a hydraulic supply with a minimal oil flow of 20L/min.

The CT 20 is available in following models:

- CT 20 N: that uses the tractor’s distributor for its movements

- CT 20 H: with hydraulic distributor

- CT 20 E: with electro-hydraulic distributor

PDF:

Features:

Machinery and Equipment End Product:

IT115 More info

Category:

Description:

The inter-row cultivator IT 115 could work in rows from 1,80m width on. The machine is projected to be mounted on the rear of the tractor, but is also possible to mount it on the front on a reversible tractor.

The machine’s head, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine has a standard equipment that consists of

- hydraulic tank

- oil cooler

- oil flow dividing valve (except for H model).

The machine is connected to the tractor by the rear 3 points and needs a PTO with 540rpm to let its hydraulic system work. It is therefore very easy to connect and it’s adaptable to any tractor on the market. Stability and precision are guaranteed by a solid and reliable frame and by the application of two mechanically regulable support wheels.

The inter-row cultivator IT 115 is available in following models:

- IT 115 H: with hydraulic distributor with 2 functions

- IT 115 E: with electro-hydraulic distributor with 4 functions

- IT 115 A: mountable on the front lifter of the tractor

- IT 110 3A: projected for a reversible tractor

PDF:

Features:

Machinery and Equipment End Product:

IT 110 More info

Category:

Description:

The inter-row cultivator IT 110 could work in rows from 1,30m width on. The machine is projected to be mounted on the rear of the tractor, but is also possible to mount it on the front on a reversible tractor.

The machine’s head, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine has a standard equipment that consists of

- hydraulic tank

- oil cooler

- oil flow dividing valve (except for H model).

The machine is connected to the tractor by the rear 3 points and needs a PTO with 540rpm to let its hydraulic system work. It is therefore very easy to connect and it’s adaptable to any tractor on the market. Stability and precision are guaranteed by a solid and reliable frame and by the application of two mechanically regulable support wheels.

The inter-row cultivator IT 110 is available in following models:

- IT 110 H: with hydraulic distributor with 2 functions

- IT 110 E: with electro-hydraulic distributor with 4 functions

- IT 110 3A: projected for a reversible tractor

PDF:

Features:

Machinery and Equipment End Product:

IT 40 More info

Category:

Description:

The inter-row cultivator IT 40 can operate in rows whose width is between 2,70m and 4,10m, perfect for wider orchards too. It is available both in the front model with bracket connection and in the reversible one with attachment on a front/rear lifter.

The machine’s heads, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs a hydraulic supply with a minimal oil flow of 25-30L/min.

Stability and precision are guaranteed by a solid and reliable frame. In the E model it is possible to install the electro-hydraulic regulation of the support wheels, while in the A model you can use the floating function of the wheels, that enables the machine to follow the soil bumps, without compromising the tools’ work.

In addition, it is possible to install a self-centring system based on mechanical sensors, that helps to keep the machine in the middle of the row, avoiding to ruin the trees.

All the movements, both those of machine and tools, can always be easily controlled by a control box in the tractor’s cabine, making possible to have a constant overlook at what happens in the row.

The IT 40 is available in following models:

- IT 40 E: with 3 points front/rear attachment

- IT 40 E CD: with an hydraulic tank that controls all the movements and engines

- IT 40 E CI: with an hydraulic tank that supplies the tools’ engines (ideal working condition)

- IT 40 A: connected to the tractor by a front bracket

PDF:

Features:

Machinery and Equipment End Product:

IT 21 More info

Category:

Description:

The inter-row cultivator IT 21 can operate in rows whose width is between 1,80m and 2,30m. It is a front-mounted machine, connected vith a bracket or on the front lifter.

The machine’s heads, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs a hydraulic supply with a minimal oil flow of 25-30L/min.

Stability and precision are guaranteed by a solid and reliable frame and by the application of two regulable support wheels with floating funtion, that enable the machine to follow the soil bumps, without compromizing the tools’ work.

All the movements, both those of machine and tools, can always be easily controlled by a control box in the tractor’s cabine, making possible to have a constant overlook at what happens in the row.

The IT 21 is available in following models

- IT 21 A: connected to the tractor by a front bracket

- IT 21 3A: projected for a reversible tractor

PDF:

Features:

Machinery and Equipment End Product:

IT 20 More info

Category:

Description:

The inter-row cultivator IT 20 can operate in rows wider than 2,20m. It is a ventral machine whose attachment is done by a bracket under the tractor’s frame. The machine is therefore in the most comfortable position for the driver, who can control all the movements from a close distance.

The machine’s head, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs a hydraulic supply with a minimal oil flow of 12-15L/min.

Stability and precision are guaranteed by a solid and reliable frame, which can be closed up once the work has been done.

The IT 20 is available in following models:

- IT 20 H: with hydraulic distributor with cable levers

- IT 20 E: with electro-hydraulic distributor with 4 functions

PDF:

Features:

Machinery and Equipment End Product:

IT 10 More info

Category:

Description:

The inter-row cultivator IT 10 could operate in rows whose width is more than 1,65m. The machine is available to be mounted both on the front and on the back of the tractor, anyway it is not a reversible machine.

The machine’s head, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs a hydraulic supply with a minimal oil flow of 12-15L/min.

Stability and precision are guaranteed by a solid and reliable frame and by the application of two regulable support wheels.

The IT 10 is available in following models:

- IT 10 H: with hydraulic distributor with 2 functions

- IT 10 E: with electro-hydraulic distributor with 3 functions

- IT 10 A: connected to the tractor by a front bracket

- IT 10 3A: projected for a reversible tractor

PDF:

Features:

Machinery and Equipment End Product:

IT 30 More info

Category:

Description:

The inter-row cultivator IT 30 can operate in rows whose width is between 2,30m and 3,30m. In its wider version, it can reach 3,70m width. It is available both in the front model with bracket connection and in the reversible one with attachment on a front/rear lifter.

The machine’s heads, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs an hydraulic supply with a minimal oil flow of 25-30L/min.

Stability and precision are guaranteed by a solid and reliable frame. In the E model it is possible to install the electro-hydraulic regulation of the support wheels, while in the A model you can use the floating function of the wheels, that enables the machine to follow the soil bumps, without compromising the tools’ work.

In addition, it is possible to install a self-centring system based on mechanical sensors, that helps to keep the machine in the middle of the row, avoiding to ruin the trees.

All the movements, both those of machine and tools, can always be easily controlled by a control box in the tractor’s cabine, making possible to have a constant overlook at what happens in the row.

The IT 30 is available in following models:

- IT 30 E: with 3 points front/rear attachment

- IT 30 E CD: with an hydraulic tank that controls all the movements and engines

- IT 30 E CI: with an hydraulic tank that supplies the tools’ engines (ideal working condition)

- IT 30 A: connected to the tractor by a front bracket

PDF:

Features:

Machinery and Equipment End Product:

CT 60 More info

Category:

Description:

The CT 60 trimmer is a single column machine projected for orchard and usable with different Lotti tools for leaf canopy management. It is mounted on the front of the tractor with a quick coupling bracket. After work it is then possible to replace the trimmer on a proper standing foot, reducing the user’s risks.

The trimmer’s column is equipped with a vertical ram of 1400mm that allows to reach a cutting height of 6m. In addition, the column is adjustable both positively and negatively, making easier going in and ouot of the rows, as teh machine could be placed in its central position. Even the post could be adjusted positively and negatively and can make a 330° rotation, enabling tthe work in any condition and in any orchard.

In addition, it is possible to mount on this machine a bridge-shaped frame, making possible to work on both sides and on the top of a single vineyard row.

The machine needs a hydraulic supply with a minimal oil flow of 20L/min.

The CT 60 is available in following models:

- CT 60 N: that uses the tractor’s distributor for its movements

- CT 60 H: with hydraulic distributor

- CT 60 E: with electro-hydraulic distributor

PDF:

Features:

Machinery and Equipment End Product:

IT 15 More info

Category:

Description:

The in-row cultivator IT 15 could operate in rows whose width is more than 2,2m. it is a reversible machine and it is set up for being mounted to a 3-point lifter. So, it could be mounted – in its different configurations – both on the front and on the back of the tractor.

The machine’s head, on which you can mount the tools, could be adjusted both positively and negatively, allowing to work also on hilly or terrace grounds.

The machine needs a hydraulic supply with a minimal oil flow of 12-15L/min.

Stability and precision are guaranteed by a solid and reliable frame and by the application of two regulable support wheels.

The IT 15 is available in following models:

- IT 15 H: with hydraulic distributor with 2 functions

- IT 15 E: with electro-hydraulic distributor with 4 functions

- IT 15 A: connected to the tractor by a front bracket

- IT 15 3A: projected for a reversible tractor

PDF:

Features:

Machinery and Equipment End Product:

470 Vicar air unit More info

Category:

Description:

Trailed or tractor mounted sprayer for trellis and GDC vineyards with 400 Duplex turbine.

The new turbine system allows the air to convey the water exactly where it's expected to be, increasing the treatment precision. Moreover, you can save up to 1/3 of the used product during the treatments, thanks to this innovative turbine system.

This sprayer should value as sample for all the other VICAR models, which can be discovered in the catalog. Each model is available in the version of tractor-mounted or trailed sprayer and can be equipped with tanks with different capacity

PDF:

Features:

- Turbine spraying system

- Adjustable spraying exits

- Adjustable nozzles

- Possibility to open-close each exit and nozzle

- Uniform air volume pumped through the turbine to all exits

- Double hot-galvanized chassis

- Fiberglass tank (trailed models)/Polyethylene tank (tractor-mounted models)

- Alluminium case

- Stainless steel turbine

Machinery and Equipment End Product:

450 Vicar air unit More info

Category:

Description:

Tractor mounted or trailed sprayer for orchards and vineyard, combinable with both polyethylene and fiberglass tanks adapt to any uses and application. The air unit can be equipped with towers of different length, so that it could suit any cultivation system.

The radial turbine is moreover able to direct the water exactly where it needs to be thanks to the air speed it moves, saving money on phytosanitary product.

PDF:

Features:

Machinery and Equipment End Product:

IT 200 More info

Category:

Description:

Electro-hydraulic double rear independent inter-row cultivator, usable with a wide range of interchangeable Lotti tools. Easy to connect to the tractor via PTO and cardan.

Thanks to its independent oil tank and its 5 pumps, it's suitable for all kind of works: soil tilling, weed removal, chopping, ploughing back, earthing-up, harrowing, inter-row and leaf canopy cleaning, desuckering and grass cutting between trees. Its self-centring system allows the machine to always keep the centre of the row in order not to damage the trees.

PDF:

Features:

- Hydraulically independent machine with its own oil tank and oil cooler

- Self-centring system

- Electro-hydraulic control box

- 13 interchangeable tools mountable on the machine and easy to swap

- The inter-row tools are equipped with an antenna-feeler to protect even the young trees.