G. Apicella

V. Martelli

R. Marziotti

Ilpra America / Rtg

ILPRA SpA

Overview:

THE COMPANY

ILPRA was founded in 1955 and quickly established a presence in the food, cosmetic and medical packaging sectors. ILPRA’s company strategy to design and produce machines in house. ILPRA is able to develop numerous patented designs at the forefront of technology based on quality, efficiency, ease of use and safety.

THE PRODUCTS

ILPRA offers more than 40 different models of machinery. These are divided in to different categories such as Foodpack, Formpack, Fill Seal and the Seal Box series of machines. This wide range of packaging machinery enables us to offer numerous customized solutions to suit many customer’s needs.

TRAY SEALERS

They are designed to match different production needs (from small up to high productions by fully automatic lines). Product can be packed only sealing or in MAP, inside pre-formed containers (PS, PP, APET CPET aluminum or coupled cardboard) sealed with lid film.

THERMOFORMING MACHINES

They are designed to satisfy for different production sizes (from small output to high production by fully automatic lines). The bottom film is thermoformed to get the required tray on the top of which the lidding film is sealed. The machine can work sealing only or in MAP.

FILL SEAL MACHINES

They are designed to satisfy different production requirements (from small output to high production by fully automatic lines). They are ideal for packaging liquid/doughy products such as yogurt, sauces, jam, soup, etc. The product is filled inside pre formed cups (made of PS, PP, APET CPET, aluminum and coupled cardboard) , on the top of which compatible pre-cut lids are sealed. The Fill Seal Film version seals and cuts film coming from reel. The ILPRA Fill Seal are available in sealing only or with vacuum/gas facilities to extend the product shelf life.

THE GROUP

ILPRA has gained over 50 years of experience in the art of packaging a wide and varies range of products. ILPRA is also able to offer the “Complete Turn Key” and “One Stop” option to our clients with advice on machinery and a wide range of suitable packaging materials.

TECNOFOODPACK

They produce and sell plastic trays for food. They offer advanced technologically thermoformed trays, available in APET, CPET, PS, PE, PP, laminated barrier containers and also injected trays with IML technology.

TECNOPACK

They deal with high technology thermosealing films for food packaging. They can supply anti-fog and barrier materials, special films suitable for pasteurization and sterilization and customized solutions on request with high quality print system up to 8 colors.

UNIMEC

Besides selling ILPRA products in Italian market, Unimec has developed its own line of packaging units which are specifically conceived for supermarkets and deli-food producers.

SABALPACK

They construct vertical packaging lines and multi-scale dosing systems, conceived for packaging in bags of oven and dry products either fresh or deep-frozen, powders and grains.

PACKAGING SOLUTIONS

The organization of the packing stage in a rational and efficient way from a technical and economic point of view is one of the key factors to get success of a product on the market. Increased automation and research of solutions as integrated and compact as possible is the new border of the sector. In addition, the packaging of the future will be the extension of product shelf life and improvement of its commercial appeal. For ILPRA the systems that reduce manual operations and can maintain the technical and aesthetic standards of packaging, hygiene, the control of the defectiveness of the products are primary aspects in the development of new packaging technologies.

ILPRA provides packaging solutions also for medical devices as diagnostics, disposable products, surgery instruments, medication, phlebology, childcare. ILPRA offers thermo-sealing and thermo-forming machines that are constructed of high quality materials and with advanced technological innovations. The complete range of machines can be customized for working in cleanrooms or any sterile environment, always granting hermetically sealed packages.

All the companies of the ILPRA Group operate according to ISO 9001:2008 compliance and their organization of production is fully internal. Before delivering, each machine undergoes the scrutiny of stringent internal test procedures, carried out with the packaging materials received from customer. This procedure also verifies that the product is in compliance both with the regulations in force and the company’s quality standards. All test procedures are carried out through certified devices. The results are at the customers’ disposal.

FILL SEAL MACHINES More info

Category:

Description:

PDF:

Features:

FILL SEAL MACHINES

They are designed to satisfy different production requirements (from small output to high production by fully automatic lines). They are ideal for packaging liquid/doughy products such as yogurt, sauces, jam, soup, etc. The product is filled inside pre formed cups (made of PS, PP, APET CPET, aluminum and coupled cardboard) , on the top of which compatible pre-cut lids are sealed. The Fill Seal Film version seals and cuts film coming from reel. The ILPRA Fill Seal are available in sealing only or with vacuum/gas facilities to extend the product shelf life.

Machinery and Equipment End Product:

THERMOFORMING MACHINES More info

Category:

Description:

PDF:

Features:

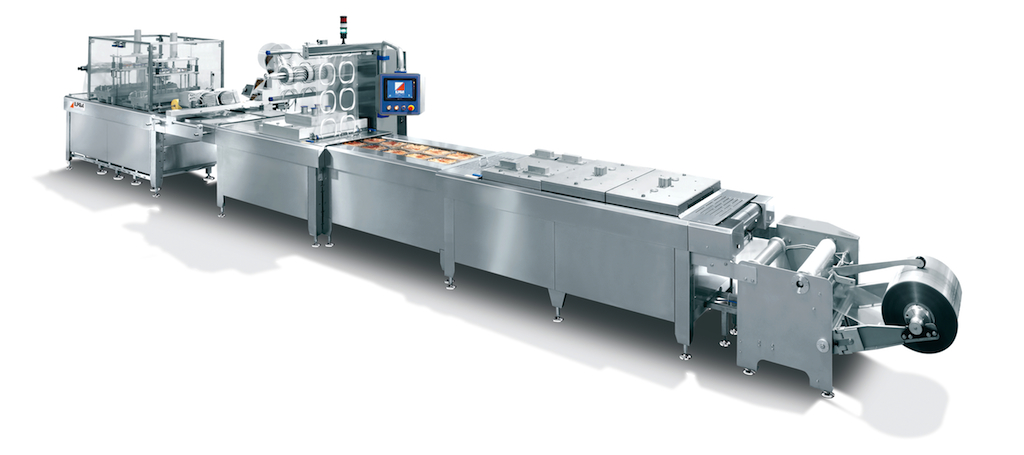

Thermoforming machines

Thermoforming machines. They are designed to satisfy for different production sizes (from small output to high production by fully automatic lines). The bottom film is thermoformed to get the required tray on the top of which the lidding film is sealed. The machine can work sealing only or in MAP.

Machinery and Equipment End Product:

SEALBOX MACHINES More info

Category:

Description:

PDF:

Features:

Seal Box Machines

This line is designed to match different production requirements (from small productions up to high productions by fully automatic lines). The Seal Box models feature the same technology and working cycling as the Fill Seal series, but are conceived to run non-destackable containers. The dosing system fill the product inside containers (made of plastic, glass and metal) on the top of which a compatible lidding film is sealed.

Machinery and Equipment End Product:

TRAY SEALER MACHINES More info

Category:

Description:

PDF:

Features:

Tray sealers

Tray sealers. They are designed to match different production needs (from small up to high productions by fully automatic lines). Product can be packed only sealing or in MAP, inside pre-formed containers (PS, PP, APET CPET aluminum or coupled cardboard) sealed with lid film.